As I stand on a modern, well-paved road, gazing at the intricate network of highways and byways stretching as far as the eye can see, I am reminded of the remarkable journey that has brought us to this point in history. The development of road networks is a hallmark of human progress, connecting communities, facilitating trade, and enabling travel. It’s a story that weaves through the annals of time, and at its very core lies a remarkable material – bitumen.

Join me as we embark on a captivating journey through history, delving into the intriguing tale of bitumen’s role in road construction. From its ancient origins to its pivotal position in contemporary road infrastructure, we’ll explore the enduring legacy of bitumen and how it has left an indelible mark on the way we connect, commute, and communicate. This is a story of innovation, engineering brilliance, and the enduring impact of a humble substance that has paved the way for human civilization to thrive. The development of road networks is a hallmark of human progress, connecting communities, facilitating trade, and enabling travel. Yet, the construction of these intricate road systems is a story woven with the threads of history, and at its heart lies a remarkable material – bitumen. So what is bitumen?

WHAT IS BITUMEN?

Bitumen is a dark, viscous petroleum product that is obtained from the refining of crude oil. It is extremely adaptable and found in many different applications, such as asphalt concrete binding, industrial waterproofing, and road construction for long-lasting road surfaces. Bitumen is suitable for a wide range of applications due to its variable properties and consistency.

EVOLUTION OF BITUMEN

The first recorded use of a bitumen road dates back to ancient Mesopotamia, specifically in the city of Babylon, which existed over 4,000 years ago. The Babylonians are credited with using bitumen to construct roadways. These early bitumen roads were constructed by mixing bitumen with various aggregates to create a durable and smooth surface.

However, if you’re asking about the first modern bitumen road, it was built much later. One of the earliest modern road construction projects involving bitumen occurred in the early 19th century in Scotland. In 1820, a Scottish engineer named John Loudon McAdam developed a road construction method known as “macadamization,” which involved compacting layers of crushed stone and then applying a bituminous binder, such as tar, to the surface. This process significantly improved the quality and durability of roads and contributed to the development of modern road infrastructure.

PROPERTIES OF BITUMEN:

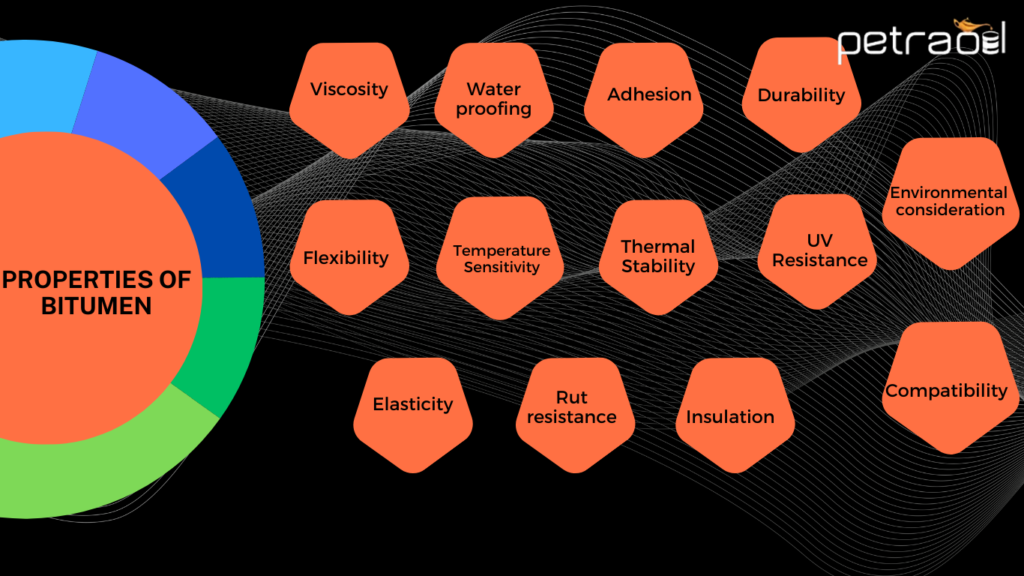

These are the key properties of bitumen

Viscosity

Bitumen is highly viscous at room temperature, which means it is thick and sticky. Its viscosity decreases as temperature increases, making it flow more easily when heated.

Waterproofing

Bitumen is known for its excellent waterproofing properties, making it ideal for sealing and protecting various surfaces, such as roofs, roads, and foundations.

Adhesion

Bitumen has good adhesive properties, allowing it to bond well with other materials like aggregate in asphalt concrete, making it suitable for road construction.

Durability

Bitumen is a durable material that can withstand the stresses and strains of traffic and weather. It has a long service life when used in construction applications.

Flexibility

Bitumen is flexible and can accommodate minor movements and deformations in the materials it seals or covers. This flexibility is important for road surfaces to withstand the weight of vehicles and changes in temperature.

Temperature Sensitivity

Bitumen’s properties change with temperature. It becomes softer and more pliable as it gets warmer and harder as it cools. This characteristic is important for its application in different weather conditions.

Thermal Stability

Bitumen can endure high temperatures without significant degradation, which is crucial for its use in hot climates and under heavy traffic loads.

UV Resistance

Bitumen is resistant to ultraviolet (UV) radiation from the sun, which helps it maintain its integrity and prevent degradation over time when used outdoors.

Elasticity

Bitumen displays elastic behavior, allowing it to return to its original shape after experiencing deformation, such as the pressure from vehicle tires.

Insulation

Bitumen has insulating properties, which make it useful for waterproofing and protecting structures from moisture infiltration.

Compatibility

Bitumen can be mixed with various aggregates and additives to create different types of asphalt mixes suitable for specific applications, such as hot mix asphalt (HMA) and cold mix asphalt (CMA).

Rut Resistance

Bitumen’s ability to resist rutting, which is the formation of depressions or grooves in the road surface due to repetitive vehicle traffic, is an important factor in road construction.

Environmental Considerations

Bitumen can be produced from a variety of sources, including crude oil and natural bitumen deposits. The environmental impact of its extraction and production can vary depending on the source and methods used.

It’s important to note that the exact properties of bitumen can vary depending on its source, grade, and intended application. Different grades of bitumen are available to meet specific performance requirements in various construction and industrial applications.

ANCIENT USE OF BITUMEN ON ROADS:

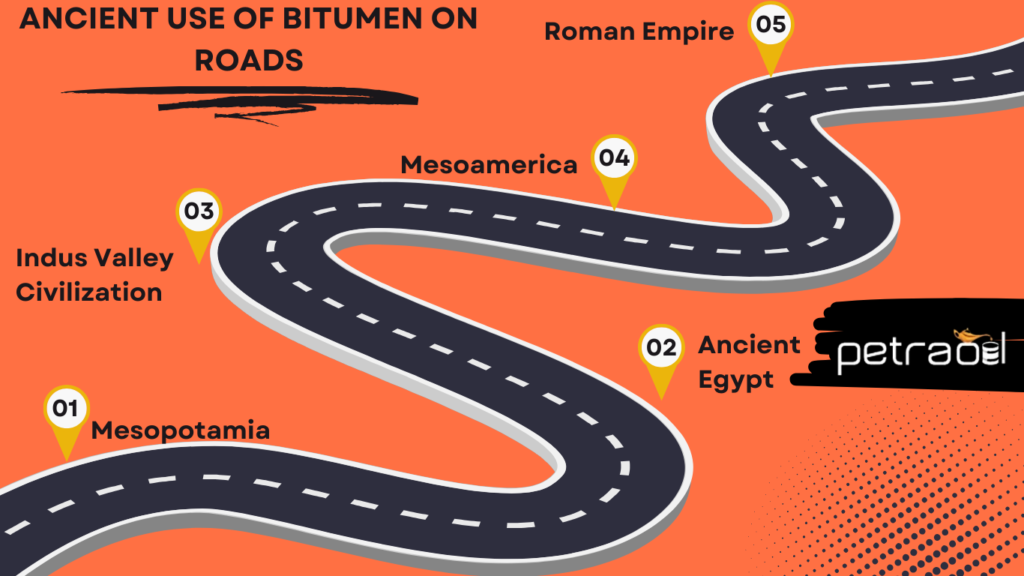

In ancient times, bitumen was employed in road construction by various civilizations. The historical use of bitumen on roads includes:

Mesopotamia

Bitumen was utilized by ancient Mesopotamian civilizations, such as the Sumerians and Babylonians, as early as 4000 BC. They mixed bitumen with other materials to create more durable and water-resistant road surfaces in their marshy and rainy environment.

Ancient Egypt

In ancient Egypt, a natural bitumen called “asphaltum” was used to pave roads and construct structures. The “Via Maris,” an ancient Egyptian road connecting Egypt to the eastern Mediterranean, featured sections paved with asphaltum.

Indus Valley Civilization

Archaeological evidence suggests that the Indus Valley Civilization, which thrived around 2500 BC in what is now India and Pakistan, used bitumen in road construction.

Mesoamerica

The Maya and Aztec civilizations in Mesoamerica used bitumen and natural asphalt to pave roads, plazas, and ball courts. They sourced bitumen from natural seepages and employed it for construction and adhesive purposes.

Roman Empire

The Romans are renowned for their extensive road network. They incorporated bitumen, among other materials, into their road construction techniques. Bitumen served as a binding agent, enhancing the strength and longevity of their road surfaces. The Roman road system played a pivotal role in their empire’s expansion.

The remarkable ingenuity with which these ancient civilizations constructed their roads truly impresses me. They cleverly combined bitumen with materials such as stone, gravel, or sand to create durable road surfaces that could endure severe weather and heavy traffic. Bitumen’s inherent adhesive and waterproofing qualities made it a wise option, particularly in areas with harsh environmental conditions.

When I think back on the past applications of bitumen on roads, I think it set the groundwork for current practices. It emphasized the material’s adaptability and durability in infrastructure development, which is still essential in today’s road building and upkeep.

MODERN DAY BITUMEN ON ROADS

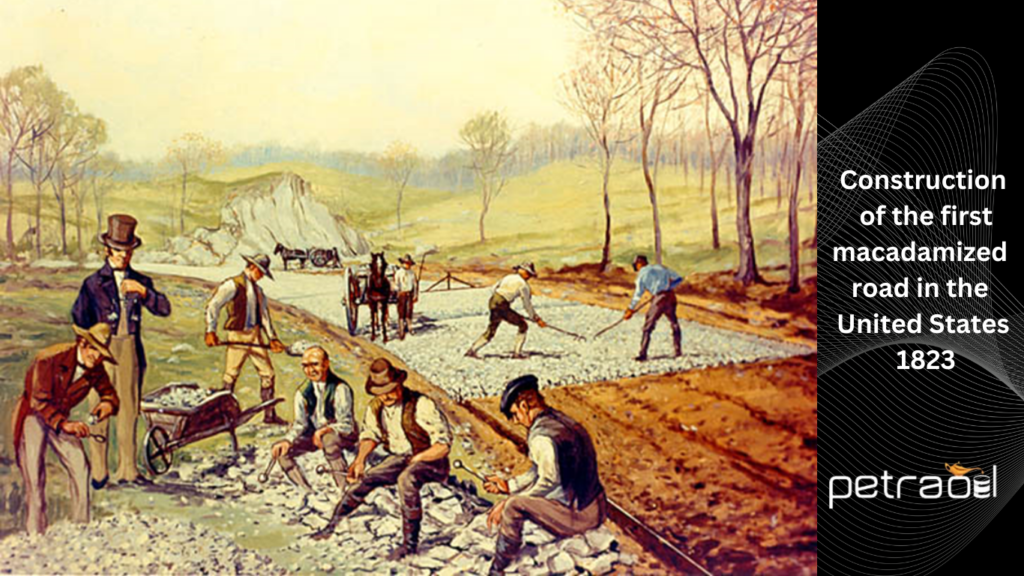

I believe that the origins of the first modern bitumen road can be attributed to the ingenious work of John McAdam, a Scottish engineer, in the early 19th century. McAdam’s groundbreaking road construction method, known as “macadamization,” involved layering crushed stone and gravel to create a solid and durable road surface. While his approach represented a significant leap forward in road construction, it did not involve the use of what we now commonly refer to as “bitumen” or asphalt. Instead, it focused on the meticulous layering of crushed stone.

It’s intriguing to me that the true introduction of asphalt road construction, where bitumen was used as a binding agent to create a smooth and enduring road surface, happened a bit later in the 19th century. In 1870, a stretch of asphalt pavement was laid on Pennsylvania Avenue in Washington, D.C., marking the outset of the modern era of asphalt road construction in the United States

So, in my view, the first modern bitumen or asphalt road, as we understand it today, emerged in the late 19th century, and the 1870 project on Pennsylvania Avenue was a pivotal milestone in the evolution of asphalt road construction.

ANCIENT VS MODERN DAY BITUMEN PROCESS

Bitumen, a versatile material used in various applications, has been produced through different processes over time. In ancient times, bitumen was sourced from natural seepages where it oozed from the earth. Ancient civilizations collected bitumen by digging pits and channels, employing containers made from materials like clay or animal hides. They allowed the bitumen to naturally evaporate in the sun, a process that could take several weeks or even months, depending on environmental conditions. After evaporation, the bitumen was filtered to remove impurities, resulting in a relatively purified form.

Modern bitumen production primarily relies on crude oil. In the oil refining process, crude oil is heated and distilled, with different components separated based on their boiling points. Bitumen is one of the heaviest fractions and is extracted using vacuum distillation. This process occurs at lower pressures and higher temperatures, allowing bitumen to be isolated without breaking down.

In modern bitumen production, quality control plays a significant role. Rigorous testing ensures that the final product meets industry standards and specific application requirements. Depending on the desired characteristics for various applications (e.g., road construction, roofing, waterproofing), bitumen may undergo blending with other components or additives.

The resulting bitumen can be packaged in various forms, such as bulk shipments, barrels, or bags, for distribution and use. Modern bitumen production is efficient and controlled, with the ability to tailor the material to meet specific performance requirements, making it an essential component in construction and industrial applications.

It’s crucial to remember that contemporary procedures are far more controlled and efficient than those from the past. The fundamentals of refining crude oil to extract bitumen are still the same, but contemporary technology and quality control guidelines have raised the end product’s consistency and calibre. Furthermore, contemporary bitumen is a versatile material in the building and industrial sectors since it can be customised to meet particular performance requirements for a range of applications.

ORIGIN OF BITUMEN IN NATURE

Bitumen, sometimes referred to as natural asphalt, is created when organic materials, mostly dead microorganisms and plant remnants, accumulate. Hydrocarbon-rich kerogen forms as a result of these materials being buried under sediment layers for millions of years and being exposed to rising heat and pressure. Kerogen can turn into bitumen when the correct circumstances are met. In the past, ancient civilizations have mined bitumen for a variety of purposes. It can seep to the surface, migrate through rocks, and be found in subterranean deposits. The composition and properties of bitumen are contingent upon its source and the prevailing geological conditions.

MAN MADE ORIGIN OF BITUMEN

The main process used to create man-made bitumen is crude oil refinement in oil refineries. Bitumen is a component of crude oil that is extracted from subterranean reservoirs or from offshore drilling. Bitumen is isolated from the heavier fractions using vacuum distillation and distillation, among other techniques. It can be combined or altered further to satisfy the demands of a given application. Strict quality control procedures guarantee that the finished product satisfies industry requirements. After processing, the bitumen is distributed and packaged for use in industrial and construction settings. Because bitumen produced artificially is a controlled and effective process, its properties can be altered to meet a range of requirements.

In my view, the future of bitumen in road construction holds exciting prospects and evolving challenges. Sustainability will take center stage, with a focus on eco-friendly production methods and recycling of materials. We can expect enhanced road performance, potentially featuring self-repairing surfaces and improved resistance to harsh weather conditions. Smart and connected infrastructure will become more common, with bitumen-based roads serving as the foundation for data collection and traffic management systems.

Alternative binders and warm mix asphalt technologies may offer more sustainable and cost-effective options. Retrofitting existing roads for increased longevity and safety will be a priority. With climate change impacts in mind, resilience and adaptation will shape road construction practices, making bitumen formulations more robust. Advanced materials and nanotechnology could introduce innovative compounds for bitumen, while 3D printing may revolutionize road construction methods.

Transportation trends, including electric and autonomous vehicles, will influence road design and construction. As we move forward, bitumen’s role in modern road infrastructure will continue to evolve, embracing innovation and sustainability to meet the demands of the 21st century.

Author: Arul Prince M